Gartner report says AR is one of the key missions in connecting workers

Table of Contents

Empowering the Future Workforce Through ViewAR’s Innovative Technology in the Paradigm Shift from Automation to Augmentation

In the Gartner Group’s outlook for 2024, they identify ten key strategic tech trends to pay attention to. One of these trends is “Augmented Connected Workforce” – a new way of thinking about how technology can be used to address a growing skills gap in the workforce. This idea of using technology to augment the capabilities of the workforce was the subject a recent white paper from the World Economic Forum (WEF).

This white paper identifies the need to transform manufacturing industry’s relationship with technology, moving on from automation, to more of a focus on augmenting the capabilities of a firm’s human resources. In highlighting a range of augmentation technologies that put people first, the WEF paper finds that many of these emerging technologies share a common user interface: Augmented Reality (AR).

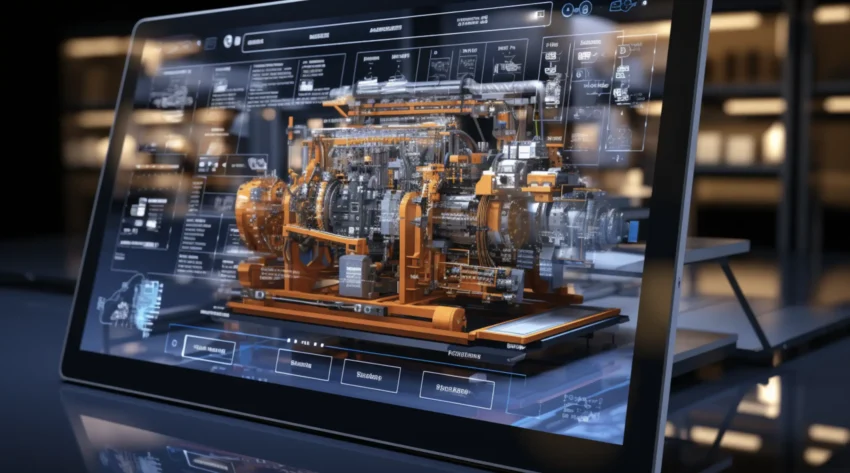

The heart of these transformational technologies is the recognition that AR is not just a tool for efficiency, but a catalyst for empowering people. The concept of augmenting the workforce, as described by Gartner, is exemplified in how ViewAR’s technology unlocks the harmonious integration of human ingenuity and technological advancements. In this blog post, we’ll dive into the benefits of ViewAR’s ServiceAR product as a critical tool to augment the capabilities of your existing and future workforce.

Benefit 1: Digitizing Knowledge for Enhanced Employee Performance

Modern manufacturing facilities present complex challenges. New employees must learn locations, procedures, and safety protocols quickly. ViewAR’s technology simplifies this knowledge digitization process.

The platform transforms tribal knowledge into accessible digital content. Workers can access information by simply pointing their phones. This reduces the learning curve in large facilities significantly. Employees navigate complex spaces safely and locate equipment efficiently.

Results from pharmaceutical manufacturing showcase ViewAR’s impact:

- Search times reduced by 60%

- Facility downtime decreased by 50%

- Faster maintenance of thousands of valves and fixtures

- Enhanced guidance for both new and experienced workers

Benefit 2: Boosting Industrial Operations

ViewAR’s workflow solutions transform complex manufacturing tasks. The system provides digital guides with context-sensitive instructions. These appear directly in the physical environment during assembly, maintenance, or quality checks.

The platform’s simple editor requires no coding knowledge. Any worker can digitize and share their expertise easily. The system also integrates with existing workflows through API connections. In automotive manufacturing, technicians follow precise guidance for complex assemblies. This builds confidence while improving productivity.

Benefit 3: Enhanced Collaboration Across Distances

ViewAR’s remote assistance tackles distance-related challenges in global manufacturing. The technology creates shared spatial awareness between field workers and remote experts. This enables immediate, context-rich knowledge sharing.

Teams collaborate as if they’re in the same location. Remote experts provide instant guidance for quick problem-solving. This feature goes beyond basic troubleshooting. It creates meaningful workplace connections through real-time collaboration.

The system proves especially valuable in precision-focused industries. Aerospace manufacturing and high-tech equipment maintenance benefit particularly well. Knowledge flows freely regardless of physical location.

Conclusion: Realizing Gartner’s Vision Through ViewAR

Gartner highlights manufacturing’s shift from automation to augmentation. ViewAR enables this transformation through three key capabilities:

- Environmental Connection: Enhanced spatial awareness for workers

- Knowledge Access: Step-by-step operational guidance

- Team Collaboration: Advanced remote assistance features

According to Gartner, manufacturing’s future depends on stakeholder collaboration. ViewAR’s AR technology creates adaptive, innovative environments. It enhances human potential beyond basic efficiency gains. The platform serves as a transformation catalyst where human augmentation drives innovation.

*[AR]: Augmented Reality

*[WEF]: World Economic Forum